When it comes to creating a professional image for your business, every detail counts. Uniforms play a significant role in creating a strong brand identity and establishing a unified look for your team. One of the best ways to achieve this look is through embroidery, a timeless decoration technique that can add a premium flair to just about any garment you could imagine.

In this blog post, we'll touch on the origins of embroidery, the benefits of embroidery as a garment decoration method and run you through the embroidery process we use here at Capital Prints. We’ll also address some common questions and concerns that we have run into over our many years in the industry.

Where Did Embroidery Originate?

Embroidery is an ancient craft that has been practiced for centuries across various cultures. The earliest examples of embroidery date back to ancient China and Egypt, where intricate designs were sewn onto clothing, tapestries, and other textiles. The art of embroidery spread to Europe during the Middle Ages, where it became a highly regarded skill among nobility and royalty. Today, embroidery is a global craft that is accessible to all. With the advent of embroidery machines in the 19th century it has become possible to produce high quality, decorated garments in record time for a very reasonable price.

Did you know - The Bayeux Tapestry, an iconic piece of embroidery, is over 70 meters (230 feet) long! Created in the 11th century, it depicts the Norman conquest of England. Despite the name, it’s a hand embroidered cloth, highlighting the artistry and storytelling of medieval embroidery.

The Benefits and Importance of Embroidery

Embroidery adds a level of sophistication to uniforms and garments that other methods just can’t match. Embroidered logos and designs provide a sense of professionalism, showing a commitment to quality and attention to detail. When these values are embodied in a well put together uniform it can hugely impact the perception of your brand among both existing and potential customers.

Beyond the ability to elevate the quality of your uniforms, embroidery can also give you great bang for buck in terms of durability. Embroidered garments can withstand frequent washing and wear while maintaining their appearance over time, more than almost any other decoration method. This is an important consideration especially if you’re operating in rigorous environments like those found in the construction or hospitality industries.

When looking at the cost-effectiveness of your Uniforms durability plays a big role. While the initial cost to decorate might be slightly higher than other methods, embroidery will ensure a longer lifespan, providing greater value over time. This is especially true when paired with long-lasting garments like jackets and headwear.

The versatility of embroidery is another great benefit because it can be applied to a range textiles and garments of varying styles, textures and weight. This versatility gives you countless ways to express your brand identity through uniforms and merch such as backpacks and tote bags. We cover the exact types of garments that work best, as well as those that don’t fare too well, a bit later in this blog post.

How Embroidery Machines Work - From

Design to Delivery

Modern embroidery machines have dramatically improved the embroidery process. It's now possible to produce great quality, highly precise embroidered garments with speed and affordability.

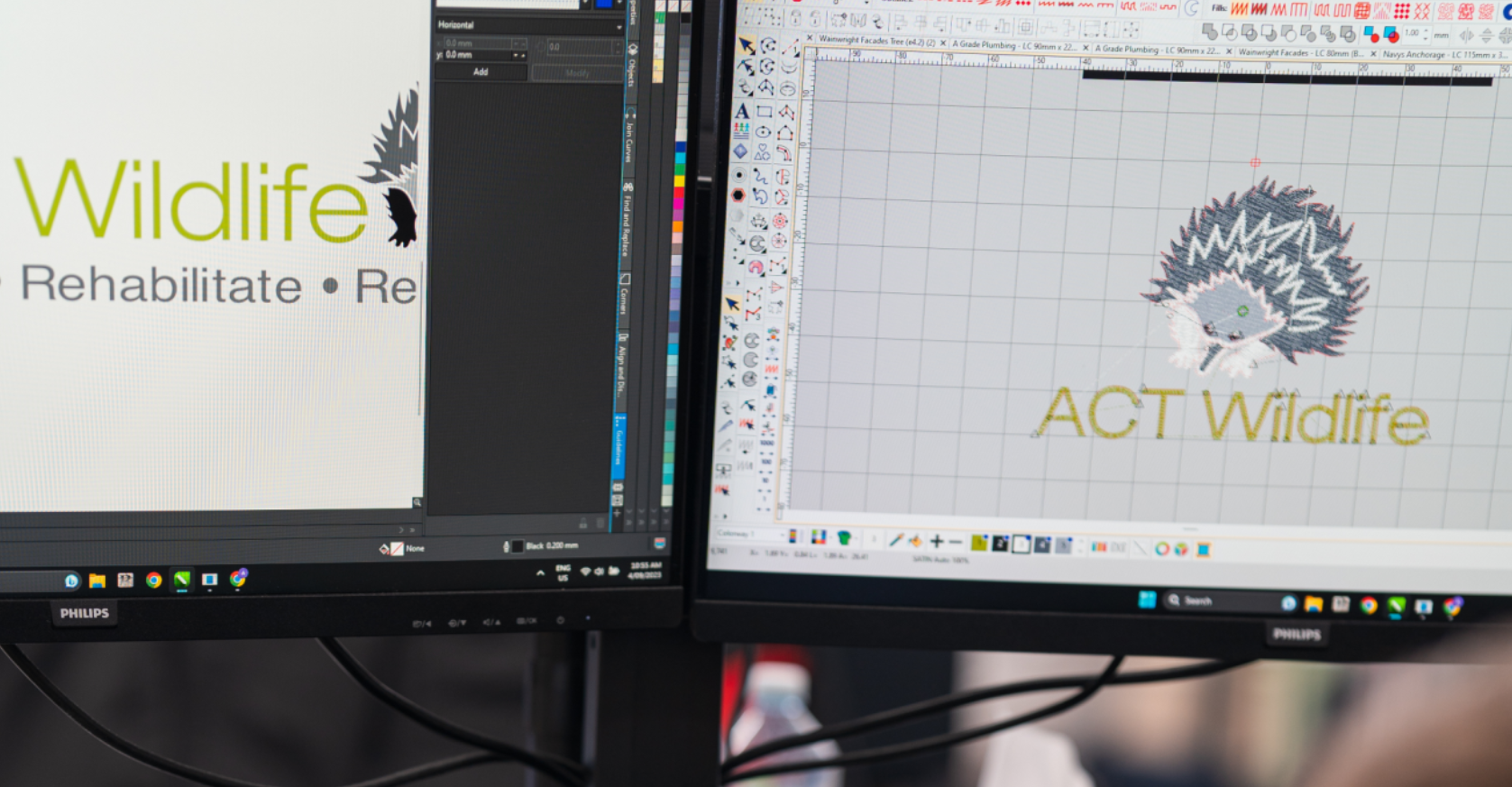

The first step in the embroidery process is digitisation. In this step we will bring an existing design into our specialised embroidery software and convert it into a format that the embroidery machine can read. Each design is unique and will need to be customised with the correct stitch type, colours and technical specifications to produce the best possible result.

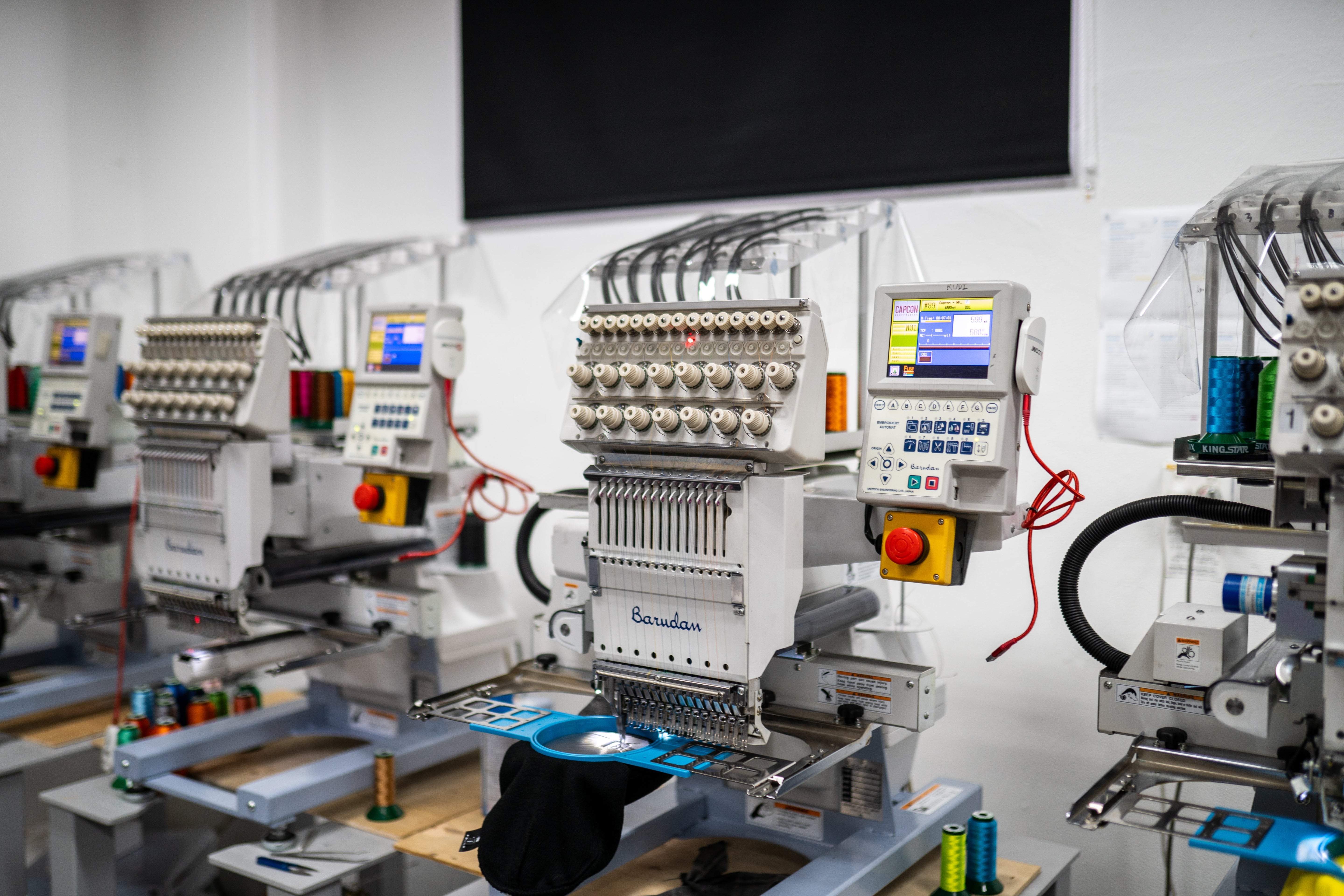

Once the file is ready, the machine can then be setup for that particular job. Different coloured threads are loaded onto the machine, corresponding to the colours in the design file. The fabric to be embroidered and a backing material is secured in a hoop, which keeps it taut and stable during the embroidery process.

The machine follows the digitised design, stitching the pattern onto the fabric and using multiple needles to switch between thread colours automatically. While the actual stitching part is automated the process still demands a keen eye for detail, an understanding of the machine's mechanics and the ability to troubleshoot any issues that arise along the way. Because of this you need highly skilled operators to watch over the entire process to ensure that the final product meets the highest standards possible.

Once the stitching is complete, the garment is removed from the hoop, and any excess threads and backing are trimmed. The attention to detail throughout this process highlights the skill and craftsmanship required to produce top-tier embroidered uniforms, from the initial digitisation all the way through to delivery of the final product.

Common Concerns About Embroidery

How Detailed Can an Embroidery Design Be?

Embroidery can achieve a reasonably high level of detail, but there are some limitations. The intricacy of the design depends on the thread thickness and the stitch type used. While fine details and small text can be embroidered, very intricate designs might lose some clarity compared to a printed image. As a general guideline, text should be at least 5mm high to ensure it is legible and sharp. When designing for embroidery, it's best to keep details bold and clear to ensure the final product looks professional. Colour gradients are possible but will only look good if the colours in the gradient are of a similar hue, for example, grey to black or yellow to orange.

An example of a well designed embroidered logo that includes both gradients and small text. Because the gradient uses colours of similar hue, they blend into each other well. The white text also sits slighty above 5mm which allows for good legibility.

Can Embroidery Be Removed?

Yes, embroidery can be removed, but the process can be time-consuming and may damage the fabric. If you need to remove embroidery, it's best to consult a professional to minimise any potential damage. You will need specialised tools and expertise to carefully unpick the stitches without harming the garment.

Will Embroidery Thread Bleed?

We only use the highest quality Kingstar thread at Capital Prints. These threads are designed to be colourfast, meaning they won't bleed or fade during washing like some cheaper threads may. Once you have received your embroidered garments you should follow the provided care instructions to maintain the embroidery's appearance. Using mild detergents and washing in cold water can help preserve the colours for a longer period of time.

What Items Are Ideal For Embroidery?

-

Polo Shirts

The smooth and tightly-knit surface is ideal for detailed designs; perfect for corporate uniforms, sports teams, and casual business wear.

- Button-Down Shirts

Firm fabric holds up well to stitching; great for adding logos or monograms on dress shirts and casual button-downs. - Jackets and Outerwear

Suitable for fleece jackets, windbreakers, and softshell jackets they will handle intricate designs and larger logos well. Puffer jackets are achievable but not recommended when dealing with small or intricate designs. - Caps and Hats

Ideal for baseball caps, beanies, and other headwear, embroidery on these items can showcase logos and brand names effectively. The more structure to the cap the better. Thin, unstructured polyester caps don’t fare so well with embroidery. - Sweatshirts and Hoodies

The weighty fabric of these items offer a good support for embroidery on the chest, back, or sleeves; popular for casual wear and team apparel. - Tote Bags and Backpacks

Perfect for sports teams, promotional items or personalized gifts. The durable fabric is an excellent canvas for embroidery design but consideration must be made when hooping these items to fit into the machine. - Workwear

Includes coveralls, medical scrubs, chef jackets, and hospitality uniforms; durable fabrics like these will happily support embroidered logos and names. - Aprons

Common in kitchens and workshops; ample space for logos and branding; strong material supports detailed stitching. - Blankets and Towels

These items aren't suitable for print application due to their raised surface however embroidery works great when the right underlay stitching is used. Great for home goods; ideal for gifts with names, dates, or special messages. - Sports and Team Wear

Jerseys, warm-up suits, and athletic apparel are frequently embroidered with team logos, player names, and numbers for a professional look. The durability of embroidery is a great benefit in these situations. Consideration should be made when looking to embroider on tight-fitting garments as the embroidery backing may cause irritation with constant repetitive activity.

What Garments Don't Fare So Well

Most garments you would find as part of a common uniform suite are fine to be embroidered upon. Despite this there are a few exceptions you will want to avoid for various reasons.

-

Waterproof garments

These should be avoided as the embroidery process will leave minor holes for the water the permeate through.

- Very thin or delicate garments

Items made of silk, lace and other lightweight knits are at risk of puckering or damage to the fabric. - Sequenced or beaded garments

These should be avoided as embroidery needles are not designed to be able to stitch through these materials. Such an event will likely cause damage to both the garment and machine -

Certain synthetic garments

Garments containing high amounts of viscose/elastane, lycra or spandex may be susceptible to puckering, stretching and distortion.

Overall, embroidering your uniforms or workwear is an excellent investment for any business. It enhances the professional appearance of your team, adds durability to the garments, and allows for various ways for you to bring your brand to life. With the right care and attention, embroidered uniforms can last years, saving you money while elevating your brand to leave a lasting impression on your customers.

Originally published by Riley Dromgold (Capital Prints).

Share:

Finding the Perfect Fit for Your Team and Your Brand

From Screen to Print: Demystifying CMYK and RGB Colour Models